CVD

Chemical Vapor Deposition (CVD)

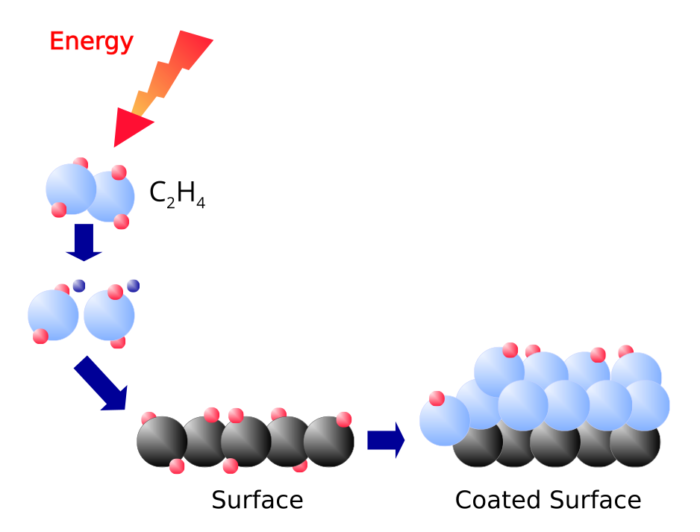

Chemical vapor deposition (CVD) is a technique to coat substrates with thin films. The coating is hereby deposited out of the gas phase by chemical reactions.

Functional principle

Classical CVD

The substrate is heated while a gas is streaming over its surface. Due to the temperature a chemical reaction of the gas molecules takes place at the surface. With the time more and more molecules are adsorbed forming a coating.

CVD can be performed in various conditions (under atmospheric pressure, in vacuum etc.).

Plasma-enhanced CVD (PECVD)

Instead of temperature the reaction energy is supplied by plasma. A Plasma contains ions that can be accelerated electrically electricallyonto the substrate. The advantages compared to the classical CVD are:

- The process temperature is low enough to coat also temperature-sensitive plastics

- Higher deposition rates are possible

- The ions can be accelerated so strong that they form a hard coating. For example in a hydrocarbon plasma a diamond-like carbon (DLC) coating can be deposited.

- On plastics the coatings are chemically bound to the surface. They therefore show the optimal adhesion.

Plasma Electronic offers the following PECVD coatings:

- Diamond-like carbon (DLC)

- Different plasma polymers

- SiOx

- SiNx

We develop all PECVD processes according to your special needs. Contact us!

info@plasma-electronic.de

Contact now